Product Warranty And Limitation Of Liability

DAVO places utmost importance on quality control, fully committed to delivering products of high standards and superior quality to our customers. We strictly adhere to international standards in our quality management system, certified by ISO9001, and follow industry best practices throughout all production processes. Our commitment is to deliver quality that exceeds expectations, ensuring that each product performs excellently and remains durable under rigorous conditions. Through these measures, we guarantee that our customers can rely on our products to meet and even surpass their needs in both performance and quality.

Our quality control process encompasses the following key steps:

Material Sourcing: We are committed to sourcing high-quality raw materials and establishing partnerships with trusted suppliers. We carefully select materials to ensure they meet our quality standards and conduct regular supply chain audits to ensure the stability and reliability of our supply chain.

Manufacturing Excellence: Our manufacturing processes are carefully designed, employing precision engineering and automated assembly techniques. From raw materials to finished products, each manufacturing step undergoes rigorous quality control and process checks to ensure product consistency and reliability.

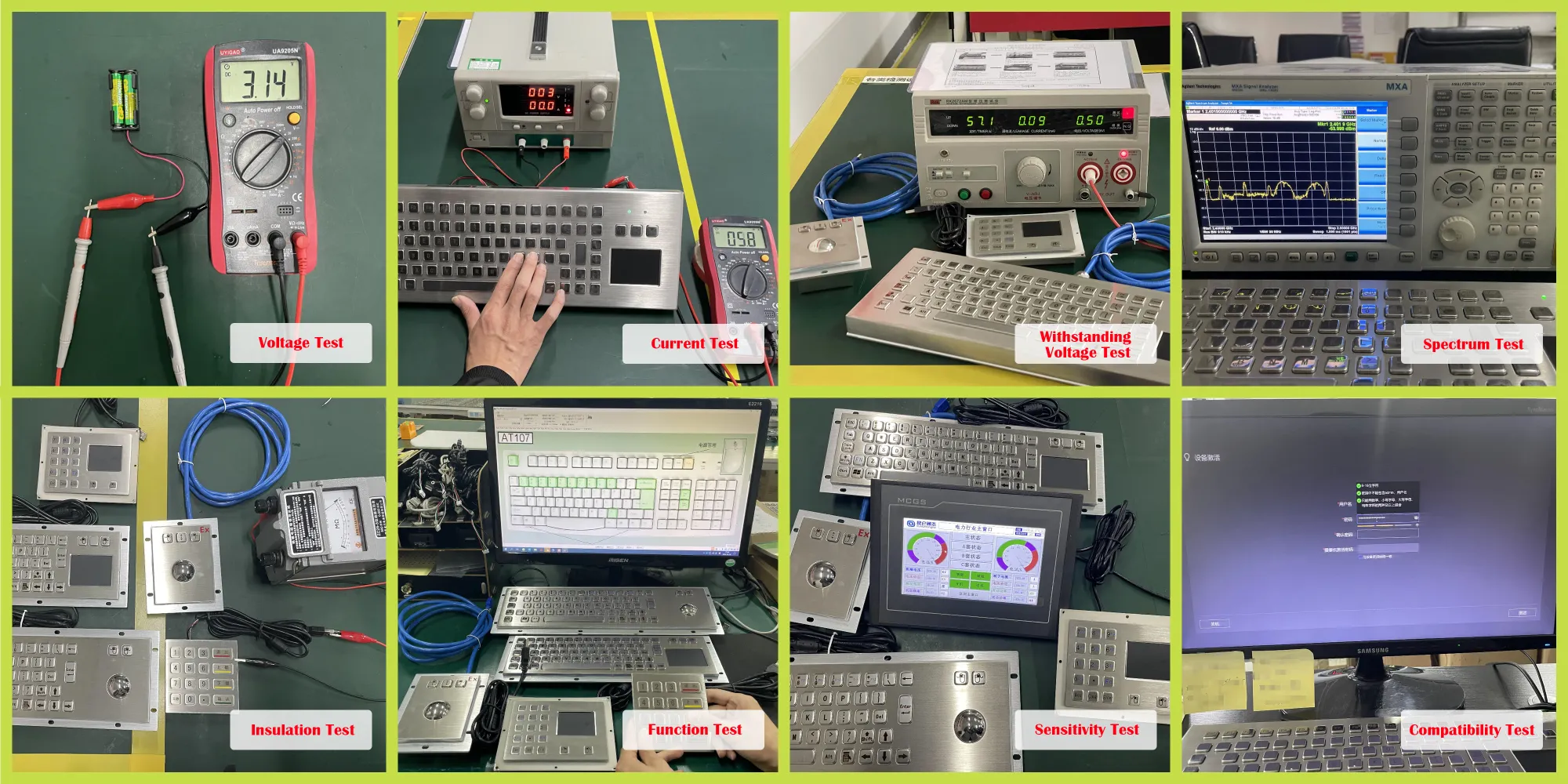

Testing and Validation: We utilize a variety of testing methods and equipment to comprehensively validate the quality and reliability of our products. These tests include both in-house testing and third-party validation to ensure compliance with various quality standards and customer requirements. Our testing equipment is state-of-the-art, covering various testing areas including performance testing, durability testing, and environmental adaptability testing.

ISO Compliant Production Cycle

Lead in Industrial Keyboard Manufacturing since 2010. Follow Quality Standard ISO9001 in production

|

|

|

Quality Assured: CE Certified KeyboardWe prioritize excellence and safety in every product we offer. Our keyboard has undergone rigorous testing and proudly bears the CE (Conformité Européenne) certification, demonstrating compliance with European Union safety and quality standards. |

Experience Eco-Friendly Excellence with Our ROHS Certified KeyboardOur keyboard has undergone rigorous testing and proudly carries the ROHS (Restriction of Hazardous Substances) certification. What does this mean for you? It means that our keyboard is crafted with a commitment to environmental responsibility. It is free from harmful substances like lead, mercury, cadmium, and more, ensuring a safer and more sustainable product for you and the planet. |

|

Choice of the Best Raw Material

Selecting the best raw materials for industrial keyboards is a strategic decision that directly impacts the keyboard’s performance, reliability, safety, and long-term cost-effectiveness. It is a critical aspect of delivering a high-quality product that meets the demands of industrial users.

Hardware

| Stainless Steel: ♦Grades: 304, 316 ♦Thickness: 0.3mm, 0.5mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm ♦Processing Methods: Laser cutting, die stamping, CNC machining ♦Surface Finishes: Brushed, fish scale pattern, electrophoresis, spray painting, silk screen printing, etching, laser printing, UV printing |

Aluminum Material: 1. Grades: 6061, 6063, 6065 2. Thickness: 1.5mm, 2.0mm, 3.0mm 3. Processing Methods: Laser cutting, die stamping, CNC machining 4. Surface Finishes: Brushed, oxidation (regular oxidation, anodized oxidation), spray painting, silk screen printing |

Plastic

AS (Acrylonitrile Styrene)

-

- Characteristics: AS is a transparent material known for its chemical stability and weather resistance. It has slightly lower heat resistance than ABS but offers higher transparency and glossiness.

- Advantages:

- High transparency and excellent gloss, making it popular for products requiring a see-through effect.

- Good rigidity and hardness, suitable for manufacturing various household items and containers.

- Relatively good chemical resistance, suitable for applications involving certain chemicals.

PC (Polycarbonate)

-

- Characteristics: PC is a high-strength engineering plastic with excellent impact resistance. It also has very good transparency, heat resistance, and weatherability.

- Advantages:

- High strength and outstanding impact resistance, maintaining good performance even at low temperatures.

- High transparency, suitable for making transparent protective gear and eyewear.

- Good temperature and weather resistance, suitable for long-term outdoor applications.

ABS (Acrylonitrile Butadiene Styrene)

-

- Characteristics: ABS is a widely used thermoplastic with good mechanical strength and overall properties, balancing rigidity, toughness, and hardness.

- Advantages:

- Excellent overall mechanical properties, especially great toughness and hardness.

- Smooth surface, easy to color and paint, suitable for producing aesthetically pleasing products.

- Good processability, can be processed by injection molding, extrusion, and other methods.

Flame-Retardant ABS

-

- Characteristics: This is a material based on standard ABS with added flame retardants to improve its safety performance in high-temperature environments such as fires.

- Advantages:

- Retains all the benefits of standard ABS, such as good mechanical properties and processability.

- Enhanced flame retardant properties, meeting specific safety requirements like flammability standards in the electronics and electrical industries.

- Maintains good physical and chemical properties while increasing the safety range of the material’s use.

Silicone

Types of Silicone: Silicone can be categorized into two types: organic silicone and inorganic silicone.

Silicone Grades:There are two main grades of silicone: Grade A and Grade B.

Grade A: Food and medical grade.

Grade B: General industrial grade.

Processing Techniques:

Compression Molded Silicone Products: These are typically produced by placing solid silicone raw material, along with a curing agent, into a high-temperature mold and applying pressure using a curing machine. The high temperature and pressure result in the solidification and shaping of the silicone product. The hardness of compression molded silicone products usually falls within the range of 30°C to 70°C. The color of the product can be adjusted using color paste according to color codes. The shape of the mold determines the final shape of the compression molded silicone product. This method is widely used in the silicone industry.

Extruded Silicone Products: These are typically produced by extruding silicone through a machine to form the desired shape. Extruded silicone products often have a long, tubular shape and can be cut to the desired length. However, the shapes that can be achieved through extrusion are somewhat limited. Extruded silicone products find extensive use in medical devices and food machinery.

Liquid Silicone Products: Liquid silicone products are created through injection molding of liquid silicone. These products are soft, and their hardness can range from 10°C to 40°C. Due to their flexibility, they are widely used in applications such as simulated human organ models and medical silicone breast pads.

Our Strict Product Performance Testing and QC Requirements

Our products undergo rigorous testing to ensure compliance with the highest standards and quality requirements. We employ a range of advanced quality inspection tools and techniques, including high and low temperature tests, electromagnetic compatibility tests, key life tests and a range of performance tests. These tools and techniques enable us to monitor and analyze product quality in real time throughout the manufacturing process and to identify and correct potential quality problems in a timely manner. Through these stringent quality control measures, we ensure that every product meets our customers’ expectations, providing them with reliable and quality products.

80°C high-temperature challengeReliability at its hottest! Our keyboards have been rigorously tested, including a grueling 80-degree high-temperature trial, proving their durability under the most sweltering circumstances |

|

|

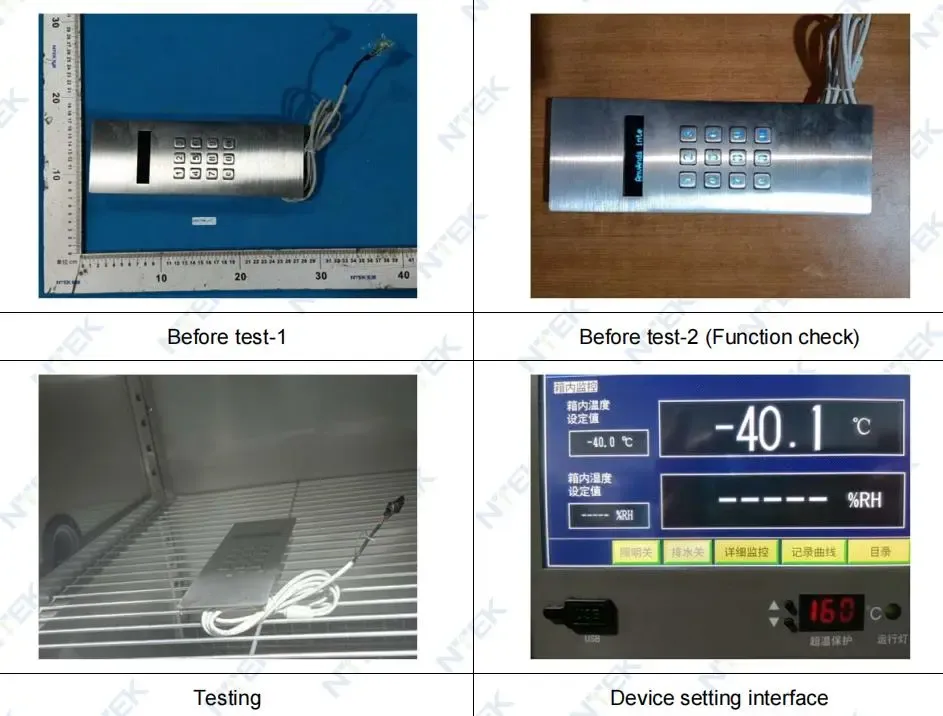

-40°C low-temperature testExtreme Temperature Resilience: Our keyboards are rigorously tested and have successfully passed the -40°C low-temperature test. This makes them ideal for use in cold storage facilities, outdoor installations, and other demanding environments where temperature extremes are a concern. |

Discover Unmatched Durability: Our Keyboards withstood over 2 Million Keystrokes!At DAVO, we take pride in engineering keyboards that redefine longevity. Our keyboards have undergone rigorous testing, with each keycap enduring a remarkable lifespan of over 2 million keystrokes. This impressive durability ensures that your typing experience remains smooth and consistent, even after years of heavy use. Explore our keyboard collection now and discover the epitome of endurance and precision in every keystroke. Quality you can trust, from a brand you can rely on. |

|

|

Experience the Power of ESD Protection with Our Keyboards – Defending Against 15KV Static Electricity!Our keyboards are engineered with the latest ESD protection technology, guaranteeing that your work environment remains free from the damaging effects of static electricity. Elevate your experience with ESD protection that stands strong at 15KV. Say goodbye to the worries of accidental static discharges disrupting your workflow. |

Davo Product Standard Testing Process

DAVO always adhere to the principle of customer first, quality first, any customer needs, we are fully committed to complete, if the customer has any questions about the product we are also fully committed to solving. We believe that in the near future, DAVO’s brand influence will stand in the world’s TOP level. Any keyboard needs and problems, please contact us!